Scope of use: Accumulation and storage of hot sanitary water from a thermal pump or high-capacity boilers.

Product material: AISI 304 stainless steel.

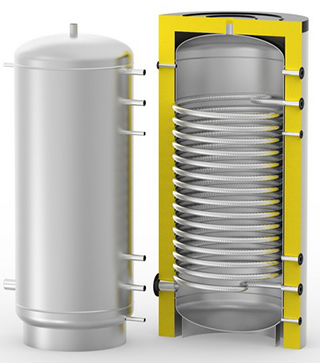

The SN-HP-Series tank has one very important feature for use with thermal pumps. The heat exchanger of this tank is much larger than that of a regular indirect heating tank. What is the purpose of this? In fact, the thermal pump, when discharging the heat it produces through the condenser, has one very important parameter, such as the temperature difference at the condenser input and output and, as a rule, in all modern heat pumps it ranges from 5 to 10°C. When this parameter is not met, the thermal pump will not provide the heating capacity and electricity consumption parameters declared by the manufacturer, and there can also be high-pressure failures in the heat pump. Therefore, the heat exchanger in our tank has a large inner diameter of 27 mm, ensuring its low friction loss and a large heat exchange area of 10 m² (optionally, more than 10 m2 can be ordered). The heat exchanger for the thermal pump should be selected based on the ratio of 1 kW capacity to 0.25 m² of heat exchanger area. For example, the heat exchanger area for a 10 kW thermal pump should be 10 x 0.25 = 2.5 m².

The tank also has a 1 1/2″ or 2″ diameter hole for electric heater installation, which may be necessary to prevent Legionella contamination.

Can be used with any heat source:

Gas-fired boiler

Solid fuel boiler

Pellet boiler

Electric boiler

Biomass boiler

Fireplace with a water jacket

Thermal pump

The tank is available in the following versions:

— fully made of stainless steel, with heat exchanger + hole for the heating element, or an inspection flange with a hole for the heating element in the flange cover.

The tank insulation is performed using NOFIRE technology with 70 mm thick, 100% recyclable polyester (which is an environmentally friendly material) with a high R-value and B-s2d0 high fire-resistance class in accordance with the European EN 13501 requirements.

On the outside, the standard design tanks with a volume of up to and including 2000 l are protected by plastic covering.

Optionally available:

Tank modification according to a customer drawing (location of connection pipes, flanges, connection diameters, type and thickness of insulation, heat exchanger size, etc.), which is calculated individually.

Be careful when choosing a hot water supply tank for a thermal pump!

For each 1 kW of heat pump capacity, there must be an area of at least 0.25 m2 for a heat exchanger built into the tank. For example, a thermal pump with a capacity of 17 kW (at B0/W35) requires a tank with a heat exchanger area equal to 17 kW x 0.25 m2=4.25 m2.

Для полного просмотра таблицы характеристик листайте вправо-влево

| Parameters | SN-HP 300 | SN-HP 500 | SN-HP 750 | SN-HP 1000 | SN-HP 1200 | SN-HP 1500 | SN-HP 2000 | ||

| Volume | liters | 295 | 485 | 703 | 995 | 1200 | 1525 | 2030 | |

| Height | Н, mm | 1570 | 1605 | 1630 | 2205 | 2120 | 2320 | 2100 | |

| Diameter | mm | 630 | 780 | 920 | 920 | 1070 | 1070 | 1350 | |

| Diameter without insulation | d, mm | 500 | 650 | 790 | 790 | 940 | 940 | 1220 | |

| Tank operating pressure | MPa | 0,6 | 0,6 | 0,6 | 0,6 | 0,6 | 0,6 | 0,6 | |

| Maximum operating temperature | °C | 95 | 95 | 95 | 95 | 95 | 95 | 95 | |

| Daily power loss | W | 240 | 400 | 560 | 810 | 970 | 1220 | 1620 | |

| Mass | kg | 76 | 98 | 114 | 142 | 185 | 211 | 257 | |

| Heat exchanger | |||||||||

| Maximum heat exchanger pressure | MPa | 0,6 | 0,6 | 0,6 | 0,6 | 0,6 | 0,6 | 0,6 | |

| Inner diameter of the heat exchanger tube | mm | 27 | 27 | 27 | 27 | 27 | 27 | 27 | |

| Maximum heat exchanger temperature | °C | 95 | 95 | 95 | 95 | 95 | 95 | 95 | |

| Heat exchanger area | sq.m | 3,2 | 4,7 | 6 | 7,3 | 9,1 | 11 | 11,0 | |

| Heat exchanger performance | |||||||||

| Continuous flow 10/45, when reaching | l/h | 510 | 1350 | 1750 | 1750 | 1750 | 1750 | 1750 | |

| tank 65 °C | |||||||||

| Recommended boiler capacity | kW | 22 | 44 | 57 | 57 | 57 | 57 | 57 | |

| Heat exchanger operating pressure | MPa | 0,6 | 0,6 | 0,6 | 0,6 | 0,6 | 0,6 | 0,6 | |

On request, a tank can be designed with operating pressure up to 10 bar.

Product Catalog

Download PDF

Installation and operating instructions

Download PDF